Remote controlled bolt drilling in shafts

Bergteamet continues to develop remote controlled shaft equipment. The latest innovation is a remote-controlled bolt drilling platform used for work in shafts.

The platform was first used in LKAB’s mine in Kiruna when the B1 shaft was renovated a few years ago. Now, an upgraded version has been developed that fits smaller shafts.

“Our goal within Bergteamet is to always improve what we do, work smarter, and most importantly, eliminate risks. This drives technological development for us,” says Magnus Bergkvist.

When it comes to tunneling, there is a wide range of machines on the market, but in shaft work, the selection is narrow.

“Moreover, the risks are greater in shafts. In tunnels, you are primarily exposed right where you are, but in a shaft, you are exposed to everything above you,” says Magnus.

Controlled by radio

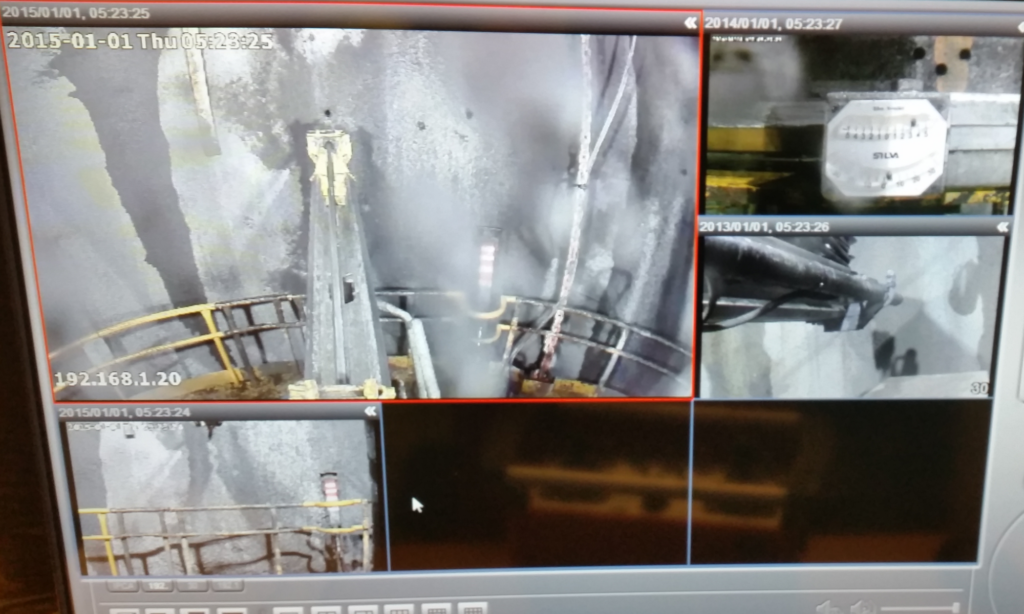

Bergteamet’s Bolt Drilling Robot consists of a hanging frame where the drilling equipment is mounted on a platform. Wheels at the top and bottom of the frame allow the equipment to run smoothly in the shaft. The robot works one row of drill holes at a time and is winched down 1.5 meters at a time. Before drilling, the shaft has been sprayed with concrete, and drilling is followed by bolting.

The robot is controlled by a machine operator who sits safely in a cabin at the level next to the shaft. Control is done with a radio control, and all communication with the equipment is wireless. The operator easily follows the work on a monitor via a camera on the platform.

Safer and faster work

One of the biggest advantages is that the work environment is improved.

“The remote-controlled Bolt Drilling Robot, combined with our Concrete Lining Robot, reduces the time people spend in the shaft by 80 percent. This means that the risks in the work are significantly reduced. A positive effect is also that the work goes faster; right now, we manage to drill about 120 holes per shift,” says Magnus Bergkvist.