Challenging reinforcement work in Malmberget

Due to seismic events in 2022, a crack appeared in one of the pillars, in the ore body Partas, close to the underground winder in Malmberget. Bergteamet fixed the crack and reinforced the room during the summer and autumn.

The pillar is located at the 940-meter level and is important because it houses the two winder engines that drive the skips for ore hoisting.

“The skip shaft is a lifeline in the mine,” says Johan Skarin, site manager in Malmberget.

High and inaccessible

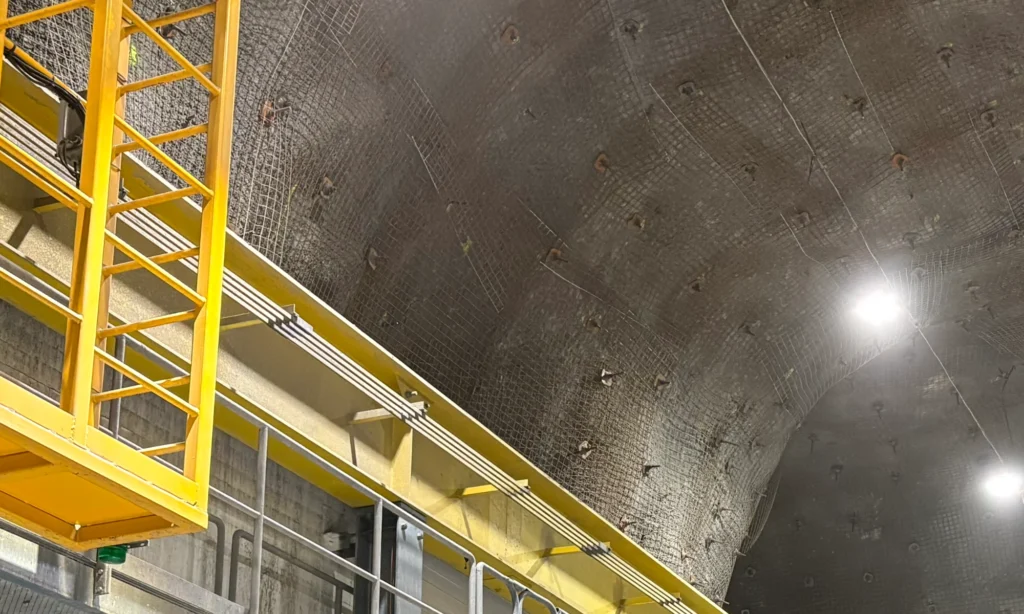

The reinforcement work was challenging and required special methods.

“It is hight to the top of the room and the physical conditions with the size and placement of the game engines meant that we could not reach everywhere with our usual rigs or use our usual methods. The solution was therefore to use a high-lift in combination with handheld machines and manual work in some areas,” explains Johan.

Manual special work

The work was carried out in collaboration between Bergteamet’s reinforcement group and shaft group. The rock reinforcement group worked with regular methods as far as possible. The shaft group supplemented with special solutions where necessary and where it was not possible to reach.

“We drilled, wired, netted, and sprayed concrete. A large part of the work was done manually by the shaft group’s four employees. They also helped to cast a support wall against the rock wall that protects the game engines a little extra,” says Johan.

No production disruptions

The work was carried out in parallel with LKAB’s mining production.

“Since ore hoisting cannot stop, we worked simultaneously. This placed extra demands on flexibility, safety, and protecting the game engines and other equipment from dust and drill cuttings, but everything went well and according to plan,” emphasizes Johan.

In December, the challenging work was completed.

“The area is now well reinforced and if nothing unforeseen happens, it should last for a long time to come,” says Johan.

Johan Skarin, Site Manager, Bergteamet